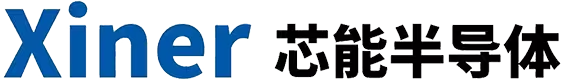

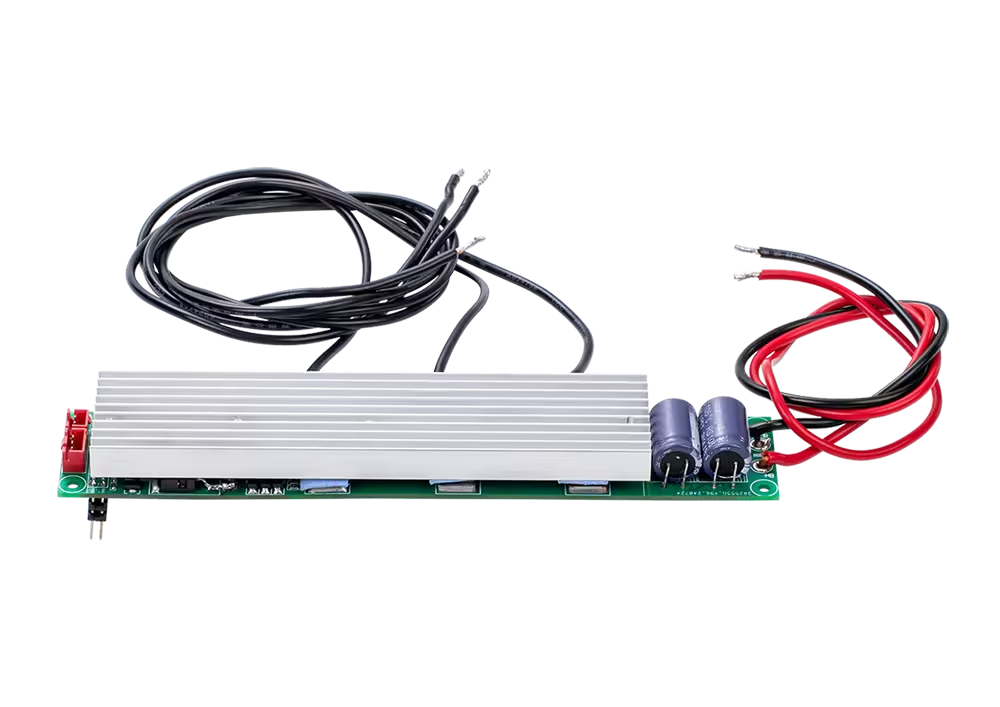

750W Sensorless FOC Solar Panel Cleaning Machine Motor Drive Board

Hero

750W Sensorless FOC Solar Panel Cleaning Motor Drive Board

The 750W sensorless FOC solar panel cleaning motor drive board is designed for photovoltaic cleaning robots and outdoor maintenance equipment. It provides smooth startup, stable speed control and slope-adaptive operation up to 25°. This BLDC motor driver board supports external speed control and auto-reverse functions for efficient solar panel cleaning systems.

Trust

Core Certification

Our Customer

Customer Testimonial

German Pool Heat Pump

U.S. Premium Air Conditioner

Welling Motor

HILTI Concrete Vibrator

U.K. Lawn Mower

BLDC Motor Functional Run Test Device for AIP

Benefits

Solution Features

• Rated power 750W, peak power 1.2kW (typical overload ≤3s)

• Input voltage DC24–45V, compatible with solar panels or lithium batteries

• Sensorless FOC + slope-adaptive control, maintains traction on 25° slopes

• Adjustable travel speed 0.2–1m/s, smooth startup, rapid acceleration

• High carrier frequency 12–18kHz for low noise and reduced EMI

• Multi-level protection: overcurrent, over/under voltage, phase loss, over-temperature, stall protection, tilt brake

• Auto-reverse cleaning program to prevent brush jamming

• IP68/IP69K design reference, dustproof, waterproof, and dust-resilient for extreme outdoor environments

• RS485/CAN dual communication support, optional 2.4GHz Mesh wireless module for multi-machine coordination

• Compact size, light weight, ideal for embedded installations

Why Choose Our 750W Solar Panel Cleaning Motor Drive Board

✅ Outdoor Reliability: Designed for harsh solar farm conditions including dust, rain, and high temperatures.

✅ High-Demand Performance: Smooth startup, fast acceleration, and torque-responsive operation for efficient panel cleaning.

✅ Energy Efficiency: Compatible with lithium batteries and external MPPT controllers to maximize solar energy utilization.

✅ Global Integration: Compact, lightweight, and supports RS485/CAN communication; optional 2.4GHz Mesh wireless for multi-machine coordination.

✅ OEM/ODM Friendly: Flexible embedded solution for solar panel cleaning systems, backed by 20+ years of motor drive expertise.

Get a Quote or OEM Service

Looking for a custom BLDC motor drive solution for solar panel cleaning robots or solar maintenance vehicles?

We provide full OEM/ODM services, including hardware design, firmware customization, and communication interface integration to meet your specific application requirements.

📩 Contact our engineering team today to get a tailored motor drive solution and accelerate your solar maintenance efficiency.

Specs

Applications

Product Applications

– Solar panel cleaning robots for PV power plants

– Automated solar maintenance vehicles

– Photovoltaic plant cleaning & maintenance systems

– OEM/ODM embedded motor drive solutions for solar applications

Form

MOQ:500-1000 pcs or Negotiable

Lead time:3–5 weeks for custom tuning

OEM/ODM:Yes

Engineering support:Yes(schematic review + parameter tuning)

About

Manufacturing

20+

300+

12,000+

10,000,000+

Production Workshop

DIP Assembly Workshop

Automation Line 2

Automation Line 1

SMT Clean Room 1

SMT Clean Room 2

Tablet Production Line

Our Partner