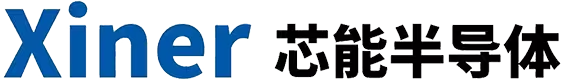

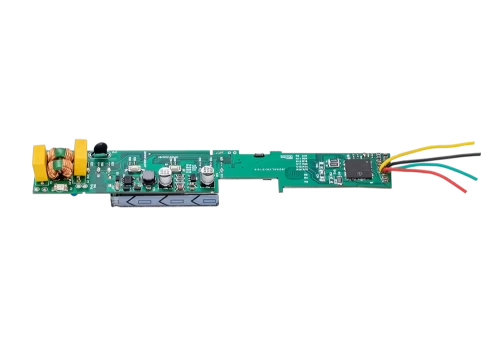

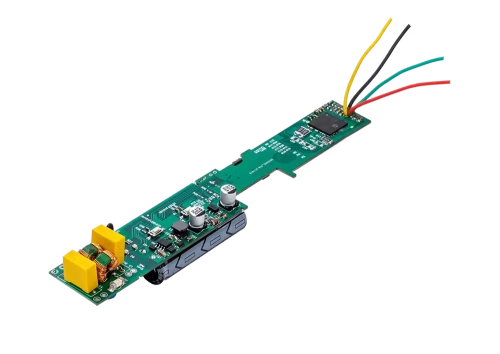

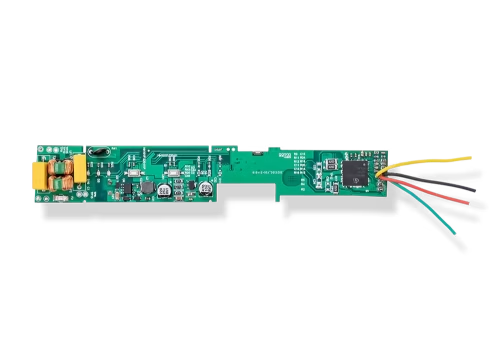

High-Speed Sensorless FOC Hair Dryer Motor Driver Board

Hero

High-Speed Sensorless FOC Hair Dryer Motor Driver Board

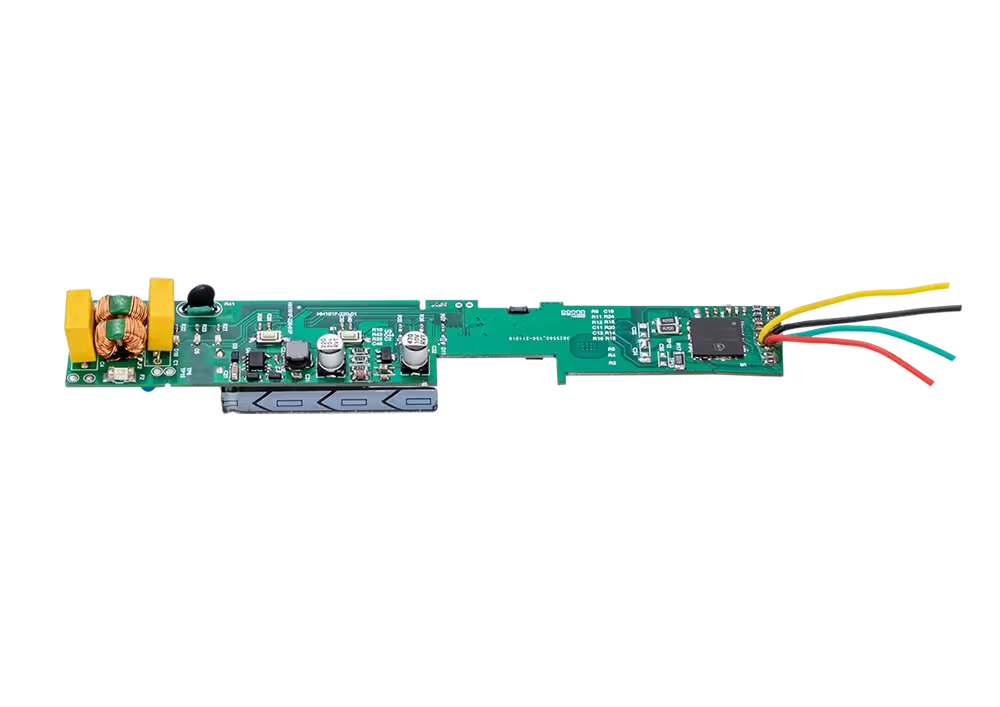

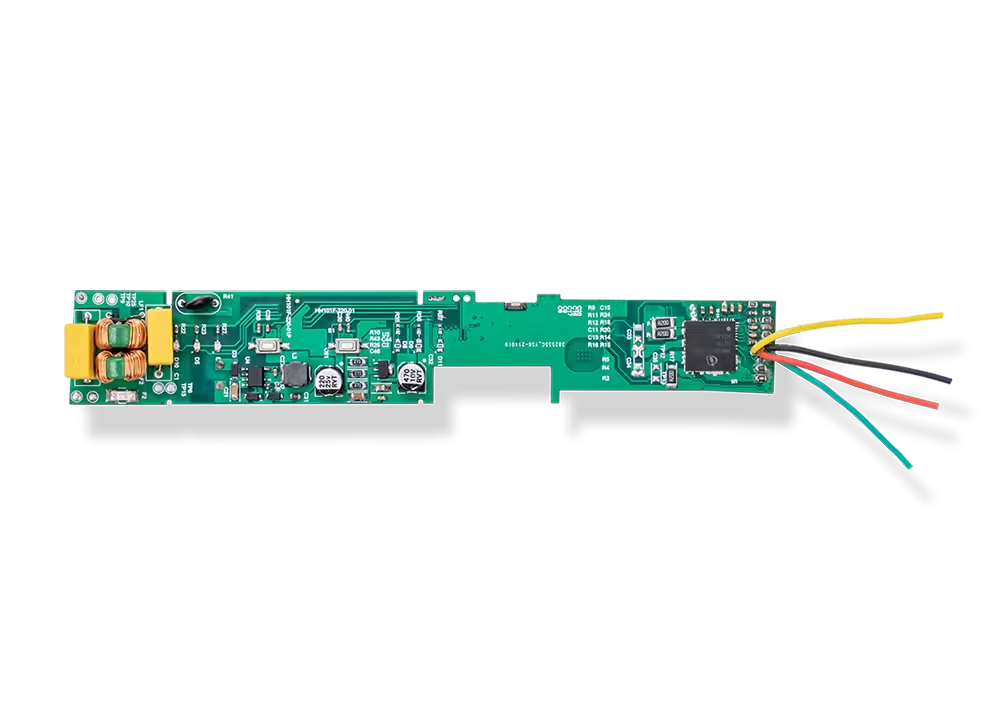

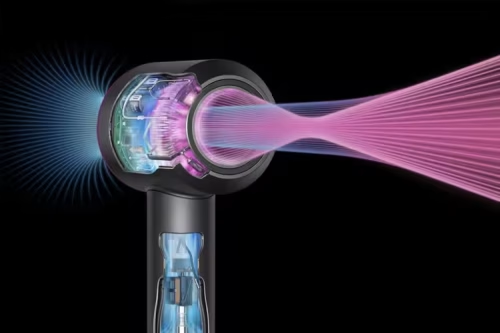

The high-speed sensorless FOC hair dryer motor driver board is designed for modern high-speed hair dryers. Featuring sinusoidal FOC control and temperature closed-loop regulation, it ensures synchronized airflow and heating control. Compact and efficient, this BLDC motor driver board enables ultra-quiet and stable high-speed operation.

Trust

Core Certification

Our Customer

Customer Testimonial

German Pool Heat Pump

U.S. Premium Air Conditioner

Welling Motor

HILTI Concrete Vibrator

U.K. Lawn Mower

BLDC Motor Functional Run Test Device for AIP

Benefits

Solution Features

• Compatible with AC220V household power, 50/60Hz global standard

• High-speed drive: 0–100,000 RPM (typical design reference)

• Sensorless FOC sinusoidal control + temperature closed-loop for airflow and heat linkage

• Smooth and rapid startup: acceleration <0.5s (typical design reference)

• SCR closed-loop temperature control for heating element, ±1°C precision

• Ultra-high carrier frequency: 80kHz, ensures low-noise operation (<45dB)

• Comprehensive protection: overcurrent, over/under voltage, phase loss, stall, overtemperature, short-circuit

• Board-level IPX4 splash-proof design

• High efficiency, compact size, low cost, and easy installation

Why Choose Our High-Speed Hair Dryer Motor Driver Board

✅ Industrial-Grade Reliability: MTBF >15,000 hours @40°C, designed for long-lasting handheld use

✅ Precision Temperature Control: Integrated SCR closed-loop control for consistent airflow and heat

✅ Low Noise Performance: 80kHz high-frequency carrier ensures whisper-quiet operation

✅ Compact & Lightweight: Easy integration for OEM/ODM handheld hair dryers

✅ Multi-Protection Design: Safeguards against phase loss, overcurrent, stall, overtemperature, and short-circuits

✅ Expert Support: 20+ years in motor control and power electronics, ready for project consultation

Our board isn’t just a motor driver — it’s a complete high-speed hair dryer drive solution engineered for modern energy-efficient and safe handheld devices.

Get a Quote or OEM Service

Looking for a reliable hair dryer motor driver or OEM partner?

We specialize in custom inverter solutions for handheld heating and airflow devices.

📩 Contact us today to discuss your project requirements —our engineering team can tailor motor driver boards, firmware, and communication protocols to your exact specifications.

Specs

Applications

Product Applications

– Home high-speed hair dryers

– Beauty & salon hair dryers

– Handheld hot air tools

– OEM/ODM motor driver integration solutions for hair dryer manufacturers

Form

MOQ:500-1000 pcs or Negotiable

Lead time:3–5 weeks for custom tuning

OEM/ODM:Yes

Engineering support:Yes(schematic review + parameter tuning)

About

Manufacturing

20+

300+

12,000+

10,000,000+

Production Workshop

DIP Assembly Workshop

Automation Line 2

Automation Line 1

SMT Clean Room 1

SMT Clean Room 2

Tablet Production Line

Our Partner