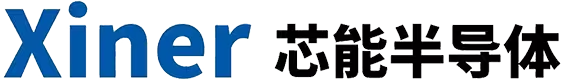

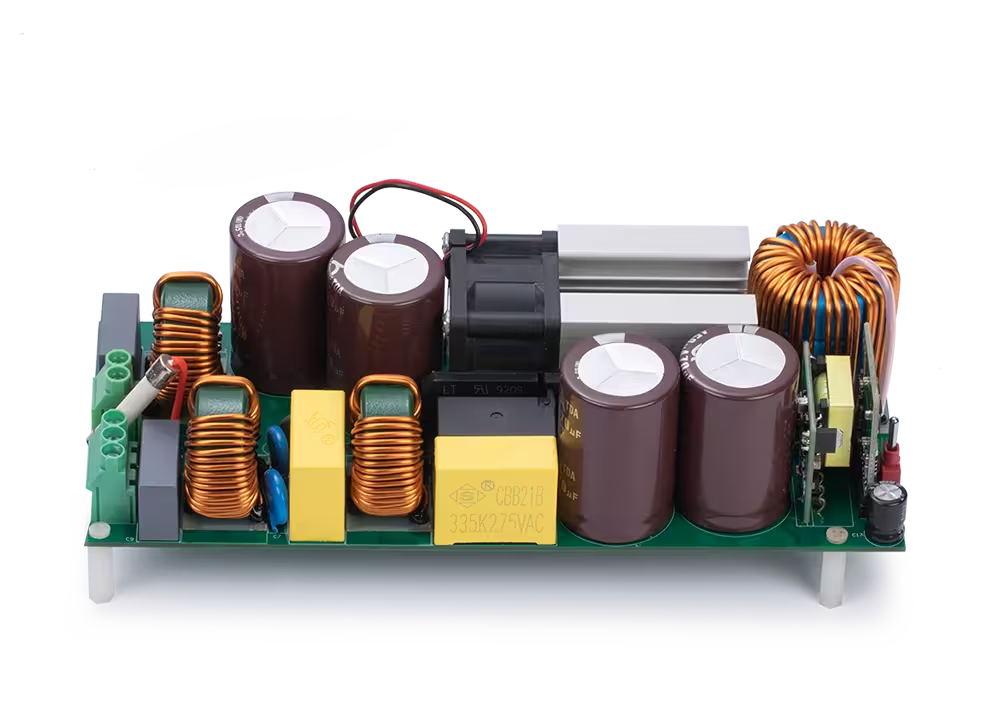

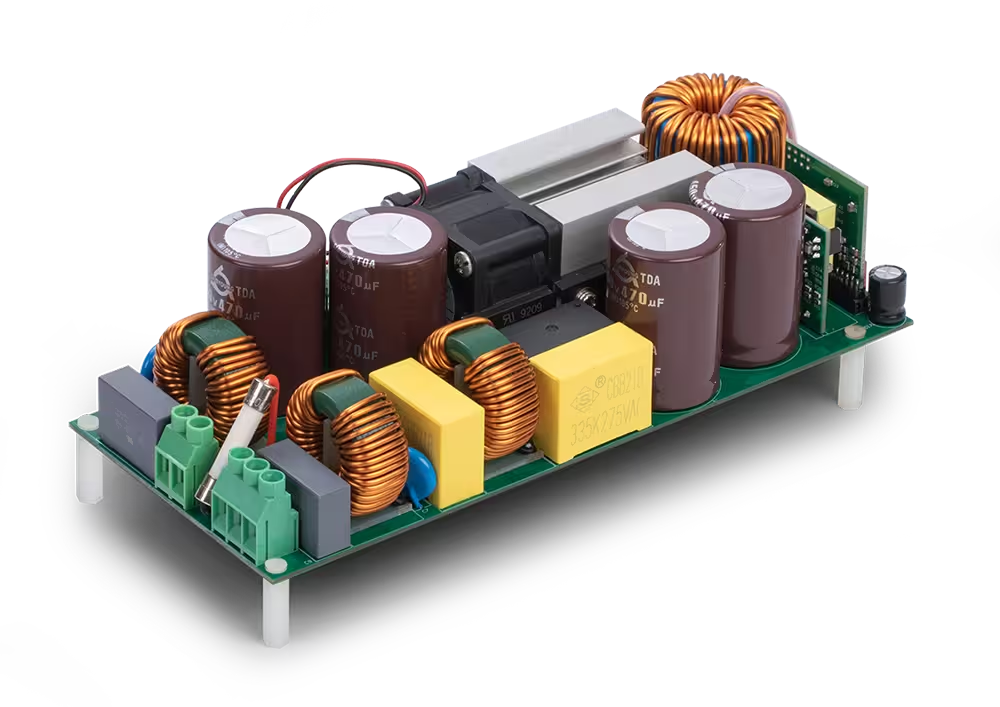

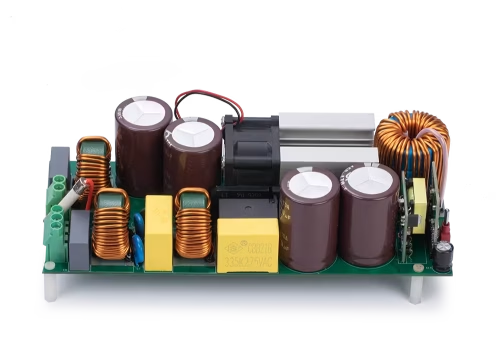

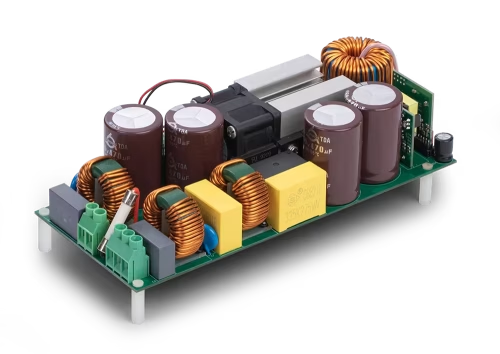

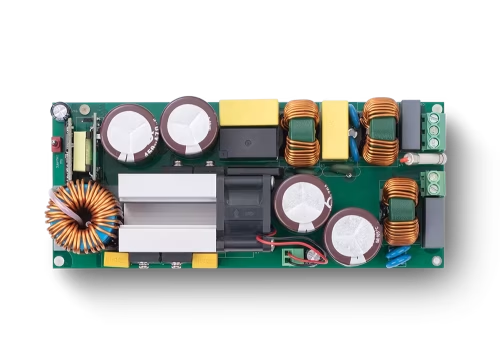

3 KW Single-Phase Digital PFC Front-end Rectifier Module

Hero

3kW Single Phase Digital PFC Front-End Rectifier Module

The 3kW single-phase digital PFC front-end rectifier module converts AC 90–264 V into a stable DC 400 V bus for motor drives and HVAC systems. Using bridgeless totem-pole PFC topology with GaN or SiC devices, it achieves PF > 0.99 and up to 98% efficiency. This PFC power module delivers clean and stable DC power for compressors and inverter drives.

Trust

Core Certification

Our Customer

Customer Testimonial

German Pool Heat Pump

U.S. Premium Air Conditioner

Welling Motor

HILTI Concrete Vibrator

U.K. Lawn Mower

BLDC Motor Functional Run Test Device for AIP

Benefits

Core Technologies

• Bridgeless Totem-Pole PFC Topology — ultra-high efficiency and low THD (< 3 %).

• Digital DSP Control — fast current-loop response < 2 ms, stable bus regulation.

• GaN / SiC Power Devices — higher switching speed, lower loss, smaller size.

• Universal Input AC 90 – 264 V — worldwide grid compatibility.

• Smart Communication: Wi-Fi / RS-485 (Modbus RTU) / TTL.

• Comprehensive Protections: OVP, UVP, OCP, OTP, SCP, overload.

• Optional Bidirectional Power Flow (DC ↔ AC) for regenerative energy feedback.

Why Choose Our 3 kW PFC Module

✅ Compact design: 200 × 150 × 40 mm footprint for easy OEM integration.

✅ Energy savings: 97 – 98 % conversion efficiency reduces heat and power loss.

✅ Flexible cooling options: air or liquid cooling for different system layouts.

✅ OEM-ready: easily customized bus voltage, interface, and thermal design.

✅ Industrial-grade reliability: MTBF > 150 000 h, proven in continuous operation.

✅ Perfect for HVAC, industrial automation and ESS manufacturers seeking high-power-factor front-end solutions.

Get a Quote or OEM Service

Partner with an experienced PFC and motor-drive solution manufacturer.

Contact us for datasheets, pricing, samples, or OEM/ODM customization of your AC-DC front-end power modules.

👉 Email us today to discuss your motor drive, HVAC or energy storage project!

Specs

Applications

Applications

– Single-phase high-power motor drives, servo systems, and VFDs

– HVAC and heat-pump AC-DC front-end converters

– Photovoltaic / energy-storage inverter systems (ESS front-end)

– UPS systems and industrial control power supplies

– Industrial test power supplies and digital-power training platforms

Form

MOQ:500-1000 pcs or Negotiable

Lead time:3–5 weeks for custom tuning

OEM/ODM:Yes

Engineering support:Yes(schematic review + parameter tuning)

About

Manufacturing

20+

300+

12,000+

10,000,000+

Production Workshop

DIP Assembly Workshop

Automation Line 2

Automation Line 1

SMT Clean Room 1

SMT Clean Room 2

Tablet Production Line

Our Partner