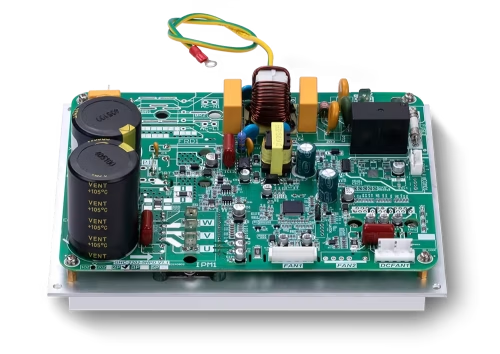

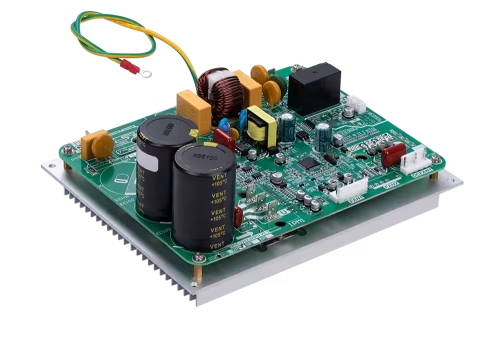

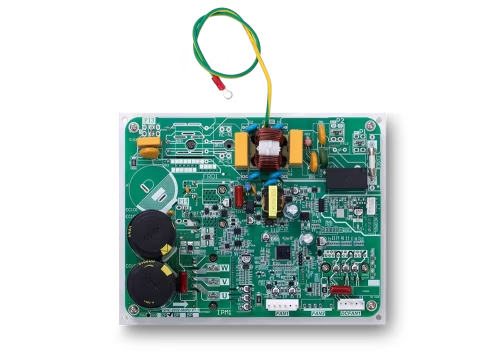

2HP BLDC Compressor Driver Board

Hero

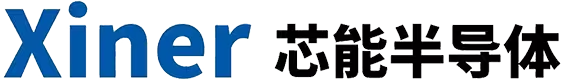

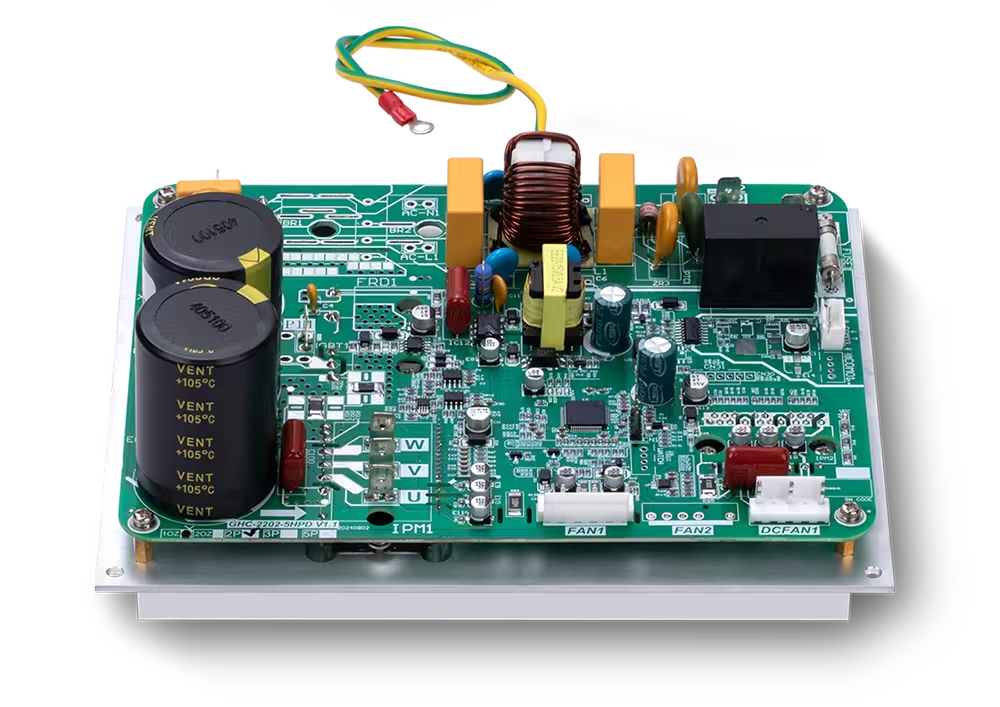

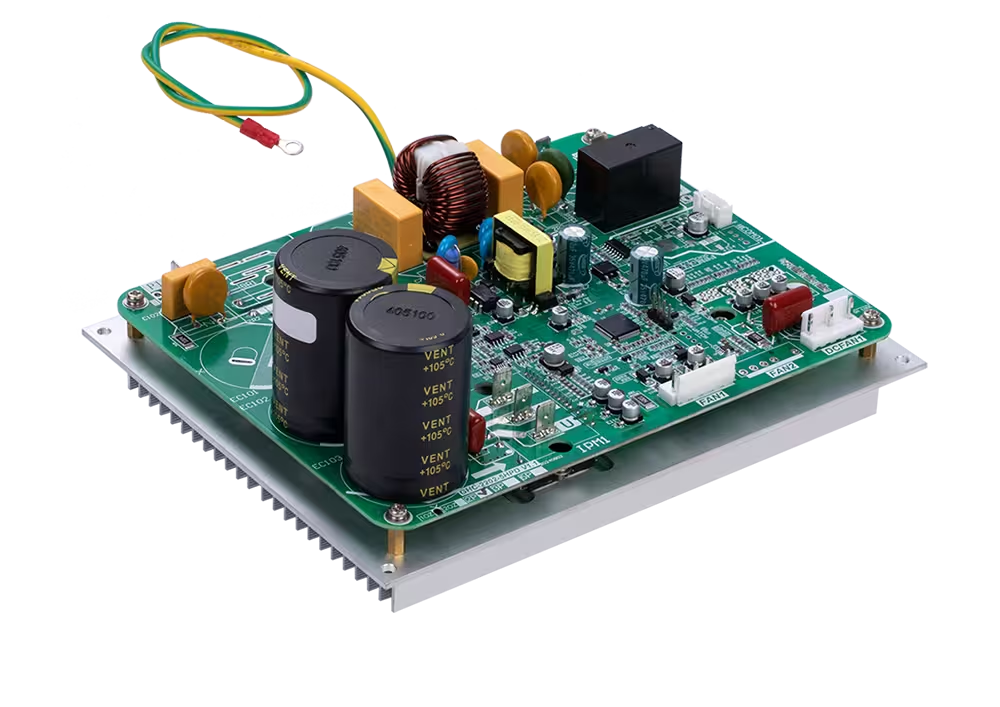

2HP Single Phase BLDC Compressor Motor Driver Board for HVAC Systems

The 2HP single phase BLDC compressor motor driver board is designed for inverter-driven HVAC and heat pump systems. It supports brushless DC compressor motors with sensorless FOC control, delivering high efficiency, low noise operation and stable performance under wide voltage conditions. Optimized for residential and light commercial HVAC applications, this inverter driver board integrates drive, protection and control functions in a compact design for OEM integration.

Trust

Core Certification

Our Customer

Customer Testimonial

German Pool Heat Pump

U.S. Premium Air Conditioner

Welling Motor

HILTI Concrete Vibrator

U.K. Lawn Mower

BLDC Motor Functional Run Test Device for AIP

Benefits

Core Features

1. FOC & MTPA Control Algorithms: Achieve smooth and efficient BLDC compressor performance.

2. Adaptive Torque Compensation: Reduces vibration and improves stability under dynamic loads.

3. 180° Pure Sine Wave Vector Control: Ensures smooth and quiet motor operation.

4. High-Frequency Flux Weakening: Expands high-speed operation range.

5. Magnetic Saturation Control: Improves motor efficiency and system protection.

6. Isolated RS-485 / UART communication: For robust integration.

7. Dual Fan Drive Modes: Supports built-in or external BLDC fan motors.

8. Customizable Cooling: Air-cooled or refrigerant-cooled heat sink options.

9. Multiple Protection Features: UV/OV protection, over current, over temperature, IPM-level safeguards.

10. High-Speed IPM/IGBT modules: Ensures low noise, low power loss, and enhanced overall reliability.

Why Choose Our Compressor Driver Board

• Self-developed FOC algorithm, supports multiple compressor brands.

• Proven low-noise and high-efficiency performance

• Multiple protection and communication options

• Built to operate reliably in –30°C environments

• Available for OEM customization (firmware, cooling, coating, protocol)

• Compact design with integrated inverter, capacitor, and filter for quick installation.

📩 Get a Quote or OEM Service

Specs

Applications

Applications

– Commercial HVAC systems (single and VRF multi-split)

– Heat pump systems (air-source, water-source, pool, dual/triple-supply)

– Refrigeration systems (refrigerators, cold rooms, freezers, freshness cabinets)

– Data Center Cabinet Cooling Components (Fans, Pumps, Valves)

Form

MOQ:500-1000 pcs or Negotiable

Lead time:3–5 weeks for custom tuning

OEM/ODM:Yes

Engineering support:Yes(schematic review + parameter tuning)

About

Manufacturing

20+

300+

12,000+

10,000,000+

Production Workshop

DIP Assembly Workshop

Automation Line 2

Automation Line 1

SMT Clean Room 1

SMT Clean Room 2

Tablet Production Line

Our Partner