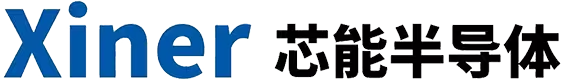

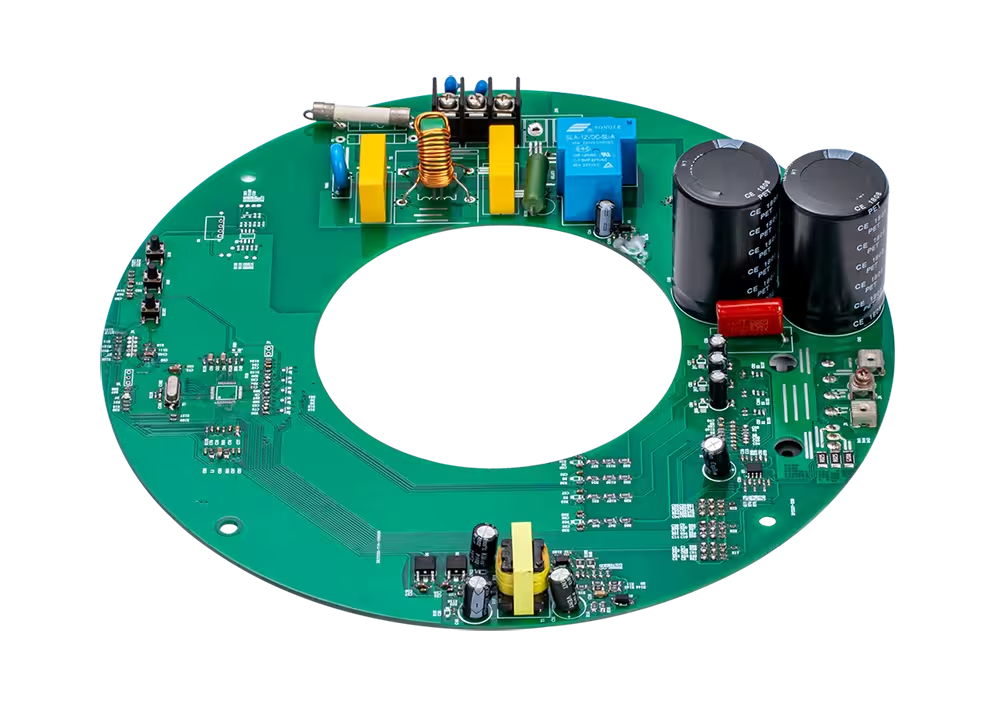

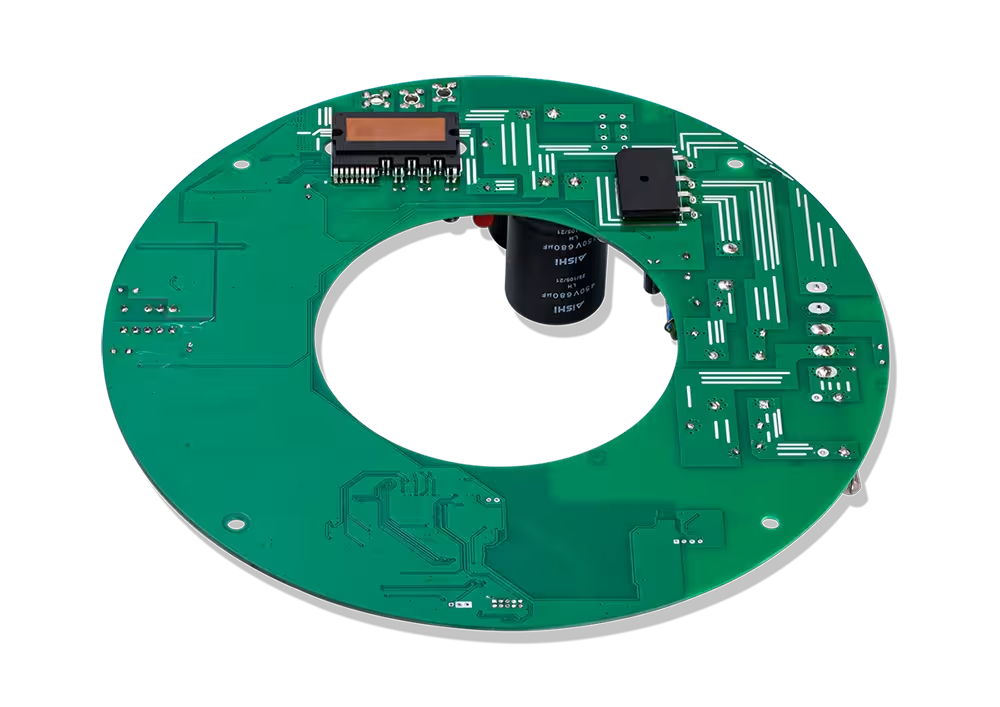

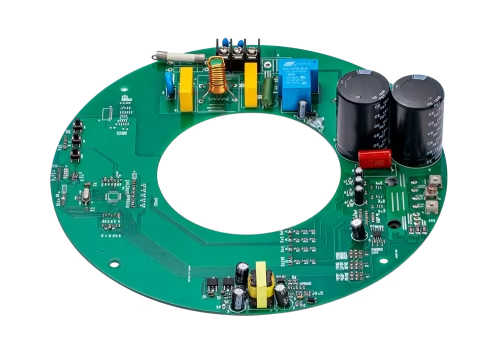

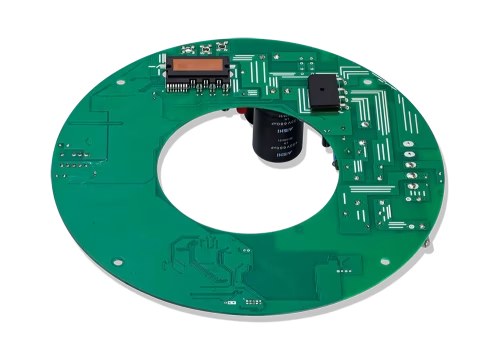

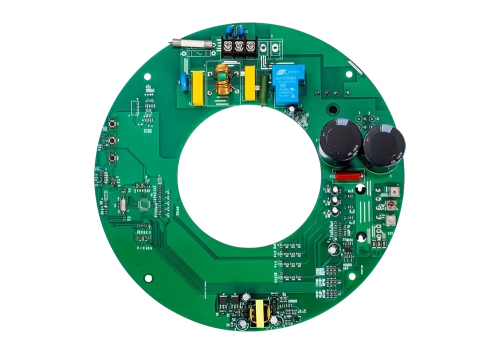

2.2kW Sensorless FOC Inverter Driver Board for Air Compressor

Hero

2.2kW Sensorless FOC Inverter Driver Board for Air Compressors

The 2.2kW sensorless FOC inverter driver board is designed for air compressors and HVAC systems. Integrating sensorless FOC motor control, active PFC circuit and comprehensive protection, it ensures high efficiency and stable compressor operation. This compact inverter driver board is ideal for OEM air compressor manufacturers seeking energy-efficient solutions.

Trust

Core Certification

Our Customer

Customer Testimonial

German Pool Heat Pump

U.S. Premium Air Conditioner

Welling Motor

HILTI Concrete Vibrator

U.K. Lawn Mower

BLDC Motor Functional Run Test Device for AIP

Benefits

Solution Features

• Rated Power: 2.2kW, Peak Power up to 3.0kW (5s).

• Wide Input Range: AC 220V ±15%, 50/60Hz.

• High Efficiency: >94% at rated load.

• High Power Factor: >0.98 with active PFC.

• Advanced Sensorless FOC Algorithm – ensures smooth and quiet motor operation.

• Comprehensive Protections: overvoltage, undervoltage, overcurrent, overload, IGBT over-temperature, exhaust overheat, and phase loss.

• Communication Interface: optional RS485 (Modbus RTU) for intelligent system integration.

• Soft Start & Smart Control: supports pressure switch or PWM signal start/stop.

• Protection Level: IP54 board-level coating for moisture and dust resistance.

Why Choose Our 2.2kW Air Compressor Drive Board

✅ Proven Reliability: MTBF > 40,000 hours at 40°C, designed for continuous industrial operation.

✅ Advanced Control: Proprietary sensorless FOC algorithm ensures smooth and efficient motor performance.

✅ High Efficiency: >94% conversion efficiency with active PFC, meeting global energy-saving standards.

✅ Global Compatibility: Supports AC220V ±15% input, ideal for worldwide compressor applications.

✅ Rugged Design: IP54 board-level protection, resistant to dust and moisture in harsh environments.

✅ Flexible Integration: Optional RS485 Modbus RTU communication for system networking.

✅ OEM Ready: Compact design suitable for HVAC, air compressor, and industrial inverter customization.

Our product is not just a motor driver — it’s a complete air compressor control solution built for energy efficiency, reliability, and long service life.

Get a Quote or OEM Service

Looking for a customizable BLDC motor drive solution for HVAC, industrial fans, or air compressors?

We provide full OEM/ODM services, including hardware layout, firmware customization, and communication protocol configuration to meet your exact system requirements.

📩 Contact our engineering team today to discuss your project and get a tailored solution.

Specs

Applications

Product Application

– Air compressors (rotary screw, scroll, and piston types)

– HVAC and heat pump compressors

– Industrial blowers and centrifugal fans

– Vacuum pumps and gas circulation systems

– OEM/ODM customized inverter control systems

Form

MOQ:500-1000 pcs or Negotiable

Lead time:3–5 weeks for custom tuning

OEM/ODM:Yes

Engineering support:Yes(schematic review + parameter tuning)

About

Manufacturing

20+

300+

12,000+

10,000,000+

Production Workshop

DIP Assembly Workshop

Automation Line 2

Automation Line 1

SMT Clean Room 1

SMT Clean Room 2

Tablet Production Line

Our Partner