18kW Industrial Fan Variable Frequency Drive (VFD)

Hero

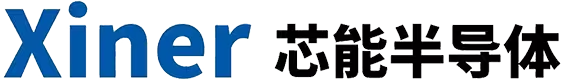

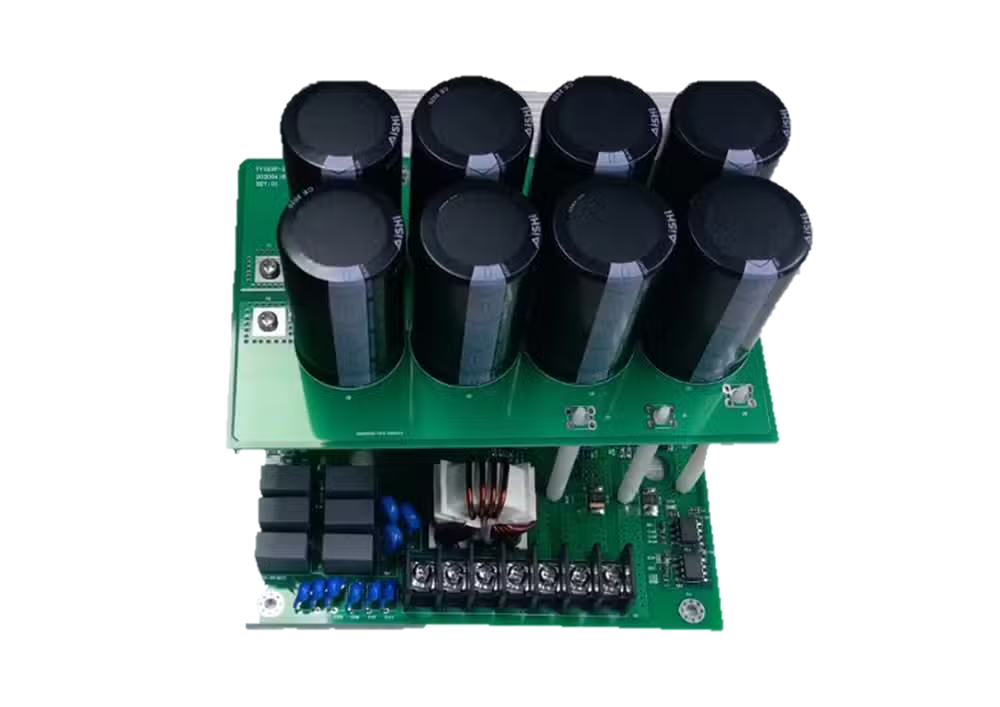

18kW Industrial Fan Variable Frequency Drive BLDC Inverter Board

The 18kW industrial fan variable frequency drive is designed for high-power industrial fans, pumps and HVAC ventilation systems. This BLDC inverter driver board delivers precise speed control, optimized energy savings and reliable continuous operation. With comprehensive protection and robust thermal design, it is ideal for OEMs and system integrators in demanding industrial environments.

Trust

Core Certification

Our Customer

Customer Testimonial

German Pool Heat Pump

U.S. Premium Air Conditioner

Welling Motor

HILTI Concrete Vibrator

U.K. Lawn Mower

BLDC Motor Functional Run Test Device for AIP

Benefits

Core Technologies

Our VFD integrates advanced digital motor control and industrial-grade protection into a single, compact module.

Built on decades of motion control expertise, it combines power and precision:

• Advanced Sensorless FOC Control:

Accurate torque and speed regulation — even without an encoder.

Stable startup for high-inertia fan loads.

Smooth operation with low acoustic noise and reduced motor heating.

• High Efficiency & Low Loss:

Up to 96–97% conversion efficiency for reduced operational cost.

Optimized carrier frequency (8–16kHz) for noise–efficiency balance.

Two-level inverter topology ensures economic, robust performance at 18kW class.

• Comprehensive Protection:

Overcurrent, Overvoltage, Undervoltage, Overload, Short Circuit, Phase Loss, and Overtemperature protection.

Hardware-level IGBT short-circuit protection (<2µs response).

Thermal derating above 85°C for enhanced lifespan.

• Industrial Connectivity:

Built-in CANopen communication.

Optional Modbus RTU for easy system integration.

Compatible with most industrial control systems.

Why Choose Our 18kW Fan Drive

✅ Industrial-Grade Reliability: MTBF > 200,000 hours @25°C

✅ Global Certifications: CE & UL 61800-5-1 compliant

✅ Compact Design: IP20-rated, cabinet-mounted for easy integration

✅ OEM Ready: Ideal for equipment manufacturers seeking a proven drive solution

✅ Energy Savings: Reduce operating cost and extend motor lifetime

✅ Expert Support: 20+ years of experience in motor control & power electronics

Our product isn’t just a frequency converter — it’s a complete fan drive solution designed for modern energy-efficient systems.

Specs

Applications

Applications

The 18kW Fan Drive is built for medium- to high-power motor control across a wide range of industries, including:

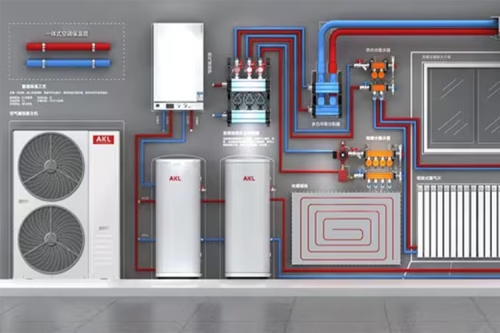

– HVAC & Heat Pump Systems — precise air volume control, improved efficiency

– Industrial Ventilation & Exhaust Systems — reliable operation under long duty cycles

– Water Pumps & Cooling Towers — smooth soft-start, lower energy consumption

– Factory Automation & Environmental Equipment — stable motor performance and protection

![]()

Form

MOQ:500-1000 pcs or Negotiable

Lead time:3–5 weeks for custom tuning

OEM/ODM:Yes

Engineering support:Yes(schematic review + parameter tuning)

About

Manufacturing

20+

300+

12,000+

10,000,000+

Production Workshop

DIP Assembly Workshop

Automation Line 2

Automation Line 1

SMT Clean Room 1

SMT Clean Room 2

Tablet Production Line

Our Partner