Next-Generation Cooling Meets Advanced BLDC Motor Driver Technology

From AI Data Centers to HVAC and Heat Pump Controller Systems

Cooling systems account for 25%–30% of global electricity consumption, making energy-efficient thermal management one of the most critical challenges in modern engineering.

From AI data centers to air conditioning systems and air source heat pump controllers, the demand for high-performance cooling is increasing rapidly.

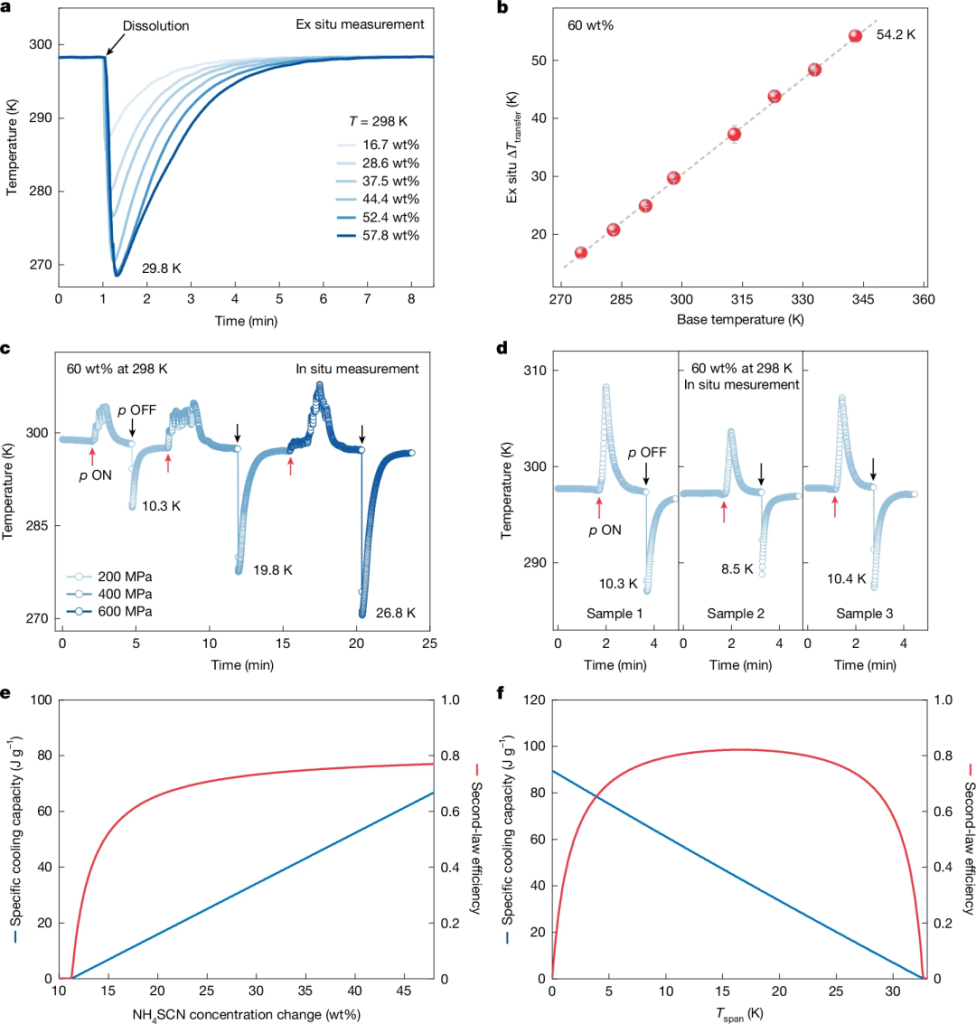

A recent breakthrough published in Nature introduces a new refrigeration mechanism with:

- 26.8K in situ temperature drop

- Cooling within 20 seconds

- 67 J/g cooling capacity per cycle

- 77% second-law efficiency

- Up to 50°C temperature drop at 60–70°C ambient conditions

This development signals a shift in how next-generation cooling systems may be designed — and highlights the growing importance of high-efficiency BLDC motor driver, inverter driver board, and power conversion systems.

Breakthrough Refrigeration Technology: Extreme Barocaloric Cooling

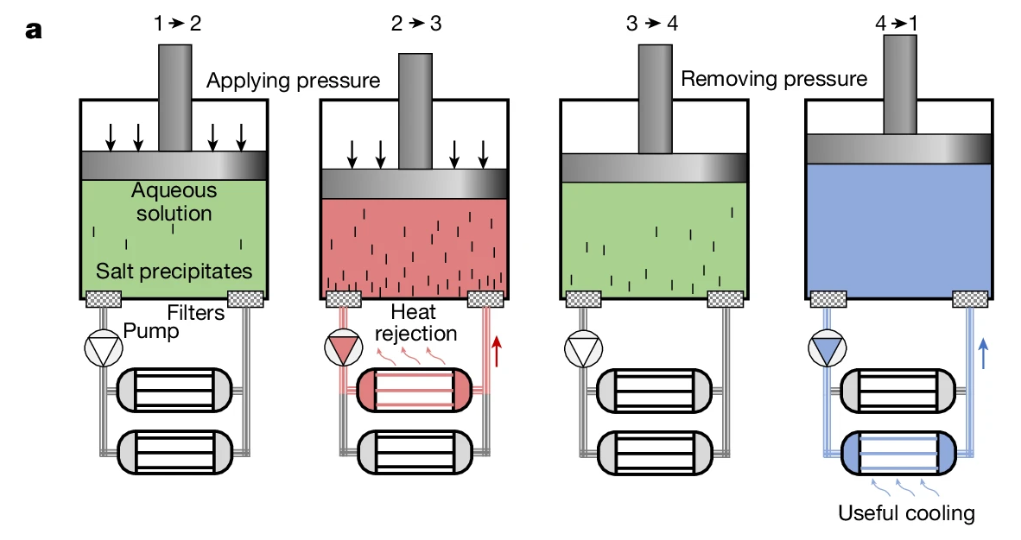

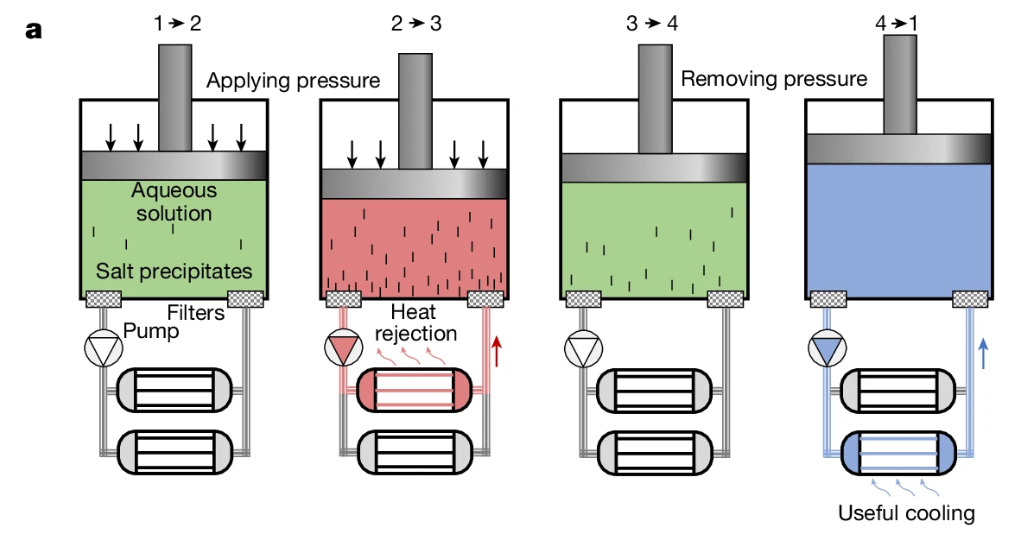

Researchers reported an extreme barocaloric effect in ammonium thiocyanate (NH₄SCN) aqueous solutions.

Under pressure control:

- Salt precipitates under compression and releases heat

- Salt dissolves upon pressure release and absorbs heat

- Achieves 26.8K temperature drop at room temperature

- Delivers 67 J/g cooling capacity in a Carnot-like cycle

- Reaches 77% second-law efficiency

For comparison:

- Vapor compression refrigeration: 30–50%

- Solid-state barocaloric systems: 50–60%

Unlike conventional systems, this dissolution-based cooling approach enables direct heat transfer, avoiding inefficient secondary fluid interfaces.

For AI server cooling, high power electronics, and industrial heat pump control board systems, this performance level is highly significant.

AI Servers, HVAC Systems, and Heat Pumps Demand Smarter Motor Control

By 2027, a single GPU may exceed 2 kW heat generation in a compact footprint.

This creates unprecedented demand for:

- High-speed cooling fans

- High-power circulation pumps

- BLDC compressor driver systems

- Intelligent HVAC controller board platforms

- Advanced heat pump controller solutions

No matter the cooling principle — vapor compression, liquid cooling, immersion cooling, or pressure-driven solution cooling — system performance ultimately depends on:

High-Performance BLDC Motor Driver and Controller Platforms

Modern cooling applications require:

- BLDC motor driver

- BLDC driver board

- Brushless motor driver board

- 3 phase BLDC driver

- Single phase BLDC motor driver

- Sensorless BLDC driver

- Sensorless BLDC motor driver

- FOC BLDC driver

- BLDC compressor driver

- High power BLDC motor controller

- 3 phase BLDC motor controller

- Brushless DC motor controller

Advanced sensorless BLDC motor controller and FOC BLDC driver architectures are especially critical for:

- High-speed server cooling fans

- Variable-speed compressors

- Air source heat pump controller systems

- High power HVAC controller board applications

As thermal density increases, motor driver board reliability and inverter driver board efficiency become decisive factors in system competitiveness.

Power Conversion Is the Backbone of Efficient Cooling

High-performance cooling systems require advanced front-end power solutions such as:

- 3 phase active rectifier

- Single phase active rectifier

- Three phase PFC

- Single phase PFC

- PFC circuit module

- PFC power supply module

- AC to DC converter board

- AC DC converter PCB

- High power AC to DC converter

- Three phase power board

Efficient power factor correction (PFC) and optimized AC-DC conversion directly influence system COP and operating cost in:

- Data center cooling systems

- Heat pump circuit board platforms

- Industrial HVAC controller board applications

In high-load environments, even small improvements in PFC efficiency and inverter driver board design translate into substantial long-term energy savings.

Why BLDC Motor Controller Technology Is Central to Next-Generation Cooling

Emerging refrigeration mechanisms with 77% thermodynamic efficiency require equally advanced motor control systems.

Future-ready cooling platforms demand:

- High power BLDC motor controller stability

- Precise FOC BLDC driver control

- Reliable sensorless BLDC motor driver operation

- Compact brushless motor driver module integration

- Intelligent heat pump control board architecture

As AI data centers scale globally, the demand for high-efficiency BLDC controller board and advanced HVAC controller board systems will continue to grow.

Hunovate: Enabling Advanced Cooling with Motor Driver and Power Electronics Solutions

At Hunovate, we specialize in:

- BLDC motor driver design and manufacturing

- Brushless motor driver board development

- 3 phase BLDC motor controller platforms

- Sensorless BLDC motor controller solutions

- Inverter driver board systems for compressors

- Heat pump controller and heat pump circuit board development

- HVAC controller board integration

- 3 phase active rectifier and PFC power supply module design

- High power AC to DC converter board solutions

Our motor driver board and power conversion platforms support:

- Air conditioning systems

- Air source heat pump controller applications

- Data center server cooling

- Industrial thermal management

As cooling science advances, drive and control technology must advance even faster.

Hunovate delivers the intelligent BLDC motor controller and power electronics foundation required for next-generation refrigeration systems.