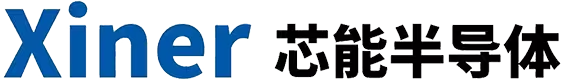

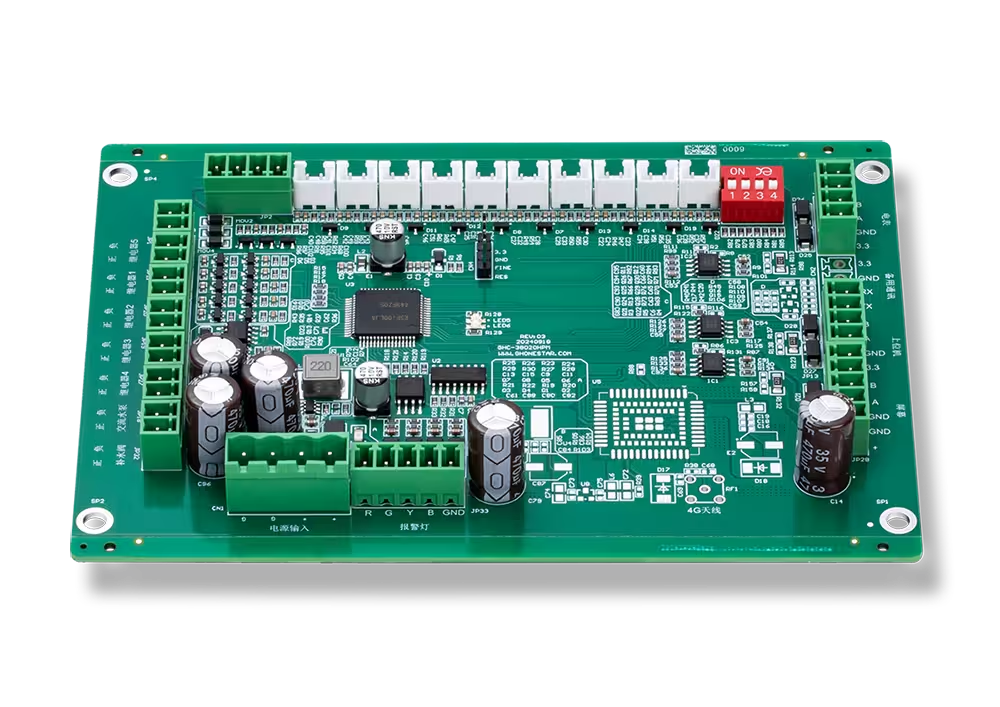

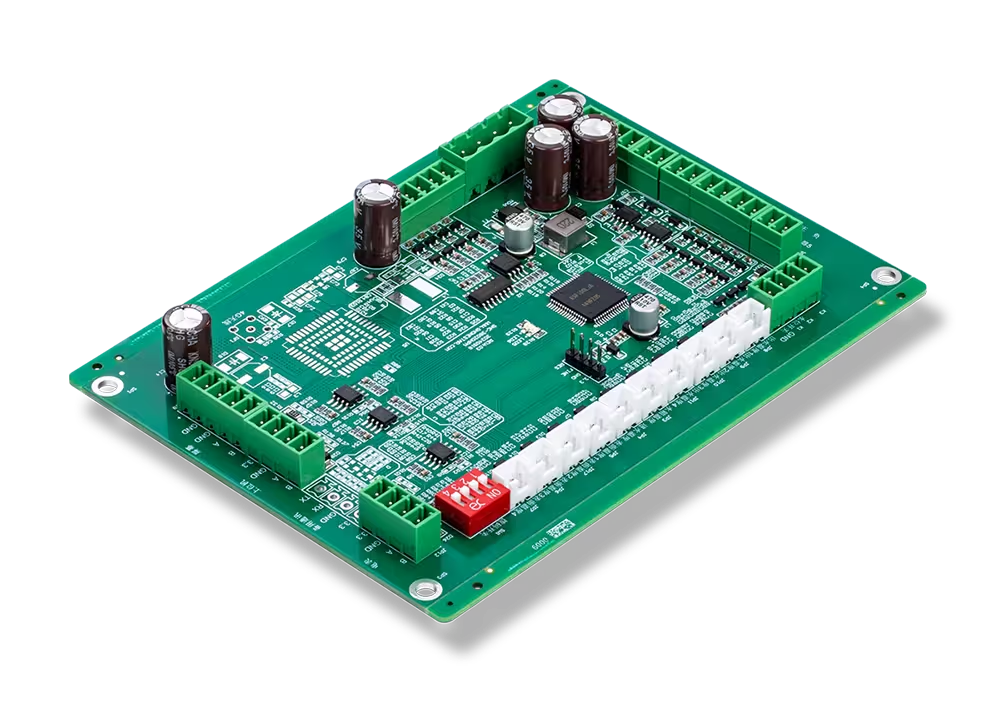

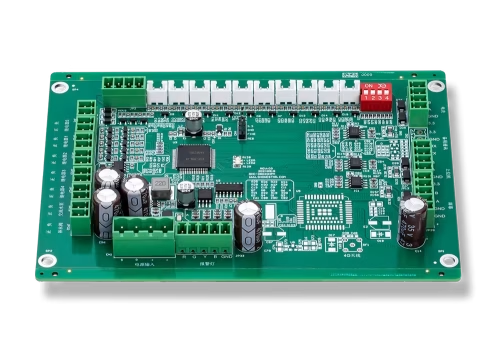

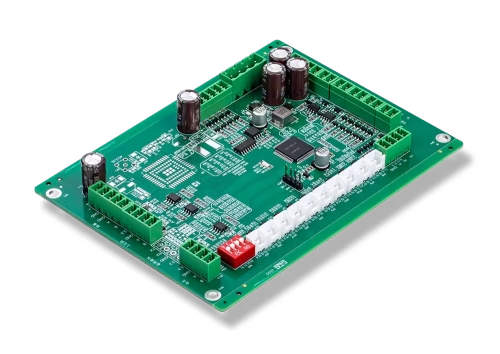

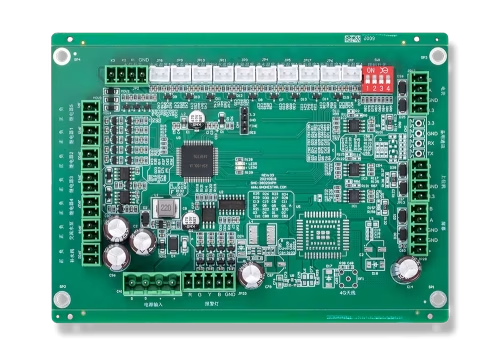

Fully Automatic Industrial Water Circulation Heating Control Board

Hero

The Fully Automatic Industrial Water Circulation Heating Control Board is engineered for industrial water heating and circulation systems.

Equipped with PLC control and fuzzy PID + feedforward compensation algorithm, it provides precise temperature regulation and liquid level management, ensuring stable operation and high energy efficiency.

This board is ideal for industrial water circulation heaters, hot water systems, and process heating applications, supporting optional touch-screen HMI and Modbus TCP/IP communication for seamless system integration and remote monitoring.

Trust

Core Certification

Our Customer

Customer Testimonial

German Pool Heat Pump

U.S. Premium Air Conditioner

Welling Motor

HILTI Concrete Vibrator

U.K. Lawn Mower

BLDC Motor Functional Run Test Device for AIP

Benefits

Solution Features

• PLC Control + Fuzzy PID & Feedforward Compensation: precise temperature and liquid level management

• Adjustable Heating Power: 0–30kW with 32-step power modulation (design reference)

• High Energy Efficiency: >96% energy-to-heat conversion

• Multi-Layer Protection: input over/under voltage, overcurrent, dry-run protection, leakage detection, and phase sequence protection

• Industrial-Grade Reliability: MTBF >100,000 hours (design reference)

• Flexible System Integration: supports optional 4.3-inch touch screen HMI and Modbus TCP/IP

• Panel-Level IP65 Protection: water spray-resistant for industrial environments

Why Choose Our Industrial Water Circulation Heating Control Board

✅ Industrial-Grade Reliability: Designed for long-term continuous operation with MTBF >100,000 hours (design reference)

✅ Precision Temperature & Liquid Level Control: PLC + Fuzzy PID + Feedforward ensures stable and accurate heating

✅ Energy Efficient & High-Performance: Up to 96% energy-to-heat efficiency

✅ Multi-Layer Protection: Safeguards against over/under voltage, overcurrent, dry-run, leakage, and phase sequence errors

✅ Flexible System Integration: Optional touch-screen HMI and Modbus TCP/IP support for OEM/ODM industrial control

✅ Panel-Level IP65 Protection: Resistant to water spray and industrial environmental conditions

This board is not just a controller—it’s a complete high-performance solution for industrial water heating and circulation systems, ready for OEM and industrial automation applications.

Specs

Applications

Product Applications

– Industrial water circulation heating equipment

– Hot water circulation systems

– Process heating and fluid circulation applications

– OEM/ODM industrial control system integration

Form

MOQ:500-1000 pcs or Negotiable

Lead time:3–5 weeks for custom tuning

OEM/ODM:Yes

Engineering support:Yes(schematic review + parameter tuning)

About

Manufacturing

20+

300+

12,000+

10,000,000+

Production Workshop

DIP Assembly Workshop

Automation Line 2

Automation Line 1

SMT Clean Room 1

SMT Clean Room 2

Tablet Production Line

Our Partner