10+

15+

12,000+

10,000,000+

300+

100+

About Hunovate

We deliver comprehensive motor drive control and digital power supply system solutions for diverse applications, including:

Commercial HVAC Control: Intelligent control systems for VRF systems, photovoltaic air conditioners, and refrigeration/freezing compressors.

Heat Pump Applications: Smart controls for heat pump water heating units (dual-purpose), European standard triple-purpose units, pool heat pumps, and ultra-low temperature heat pumps.

Industrial Motor Drives: Solutions for BLDC/PMSM motors, industrial equipment, fans, and pumps.

High-Power Power Supplies: 3-20kW PFC supplies, 2.5kW bidirectional inverter supplies, heat pump-specific and high-reliability industrial power supplies.

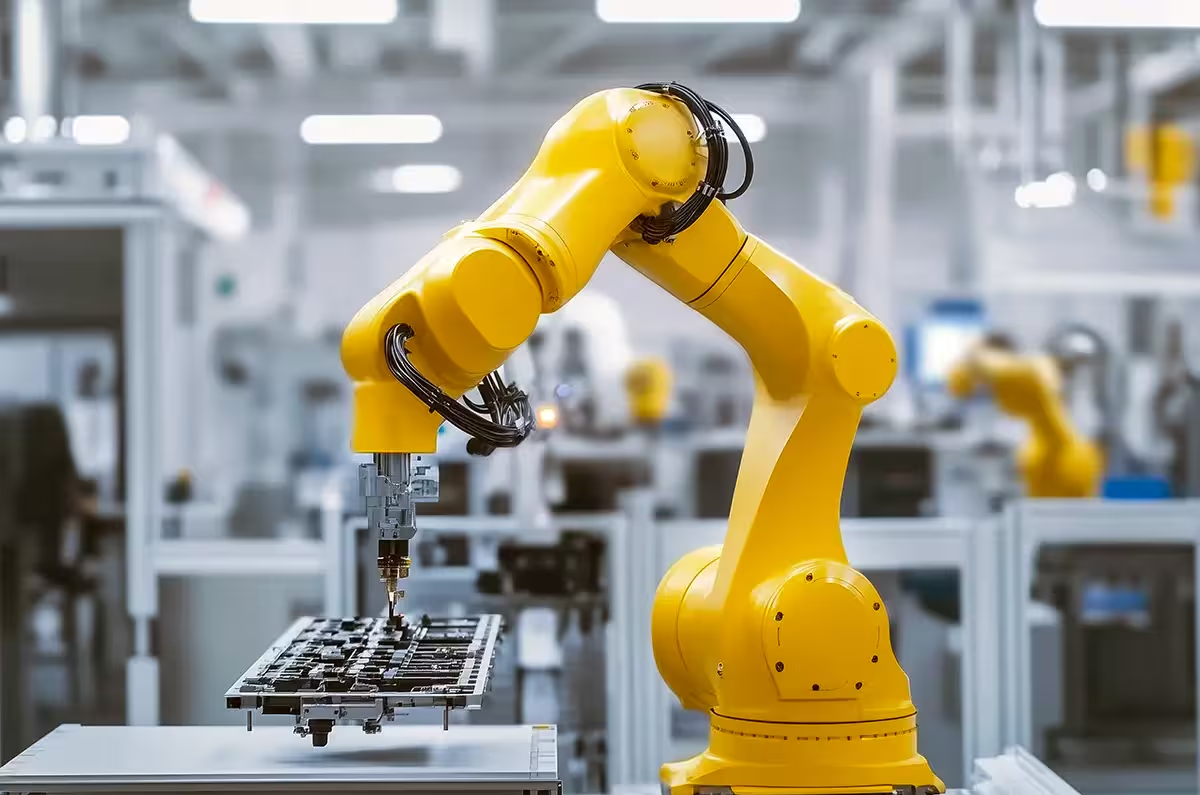

One-stop Motor Control & Power Electronics Solutions

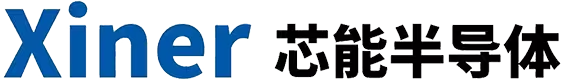

HVAC System Solution

When high-order harmonics push EMC over limits, traditional designs incur extra filtering cost; low-frequency compressor vibration triggers system resonance; insufficient PFC efficiency drives up operating expense. As a leading provider of VRF air conditioning system and HVAC variable refrigerant flow systems solutions, our BLDC motor controller and 3 phase brushless motor driver technologies deliver:

• 180° Sine Wave Vector Control (torque ripple < 5%) — ideal for 3 phase brushless motor driver applications.

• Adaptive Vibration Suppression (mechanical vibration reduced by 50%) — makes for a more reliable compressor driver board.

• High-Frequency Flux-Weakening Technology (speed regulation range 15:1)— ensures constant torque over a wide speed band.

• MTPA Control (copper loss reduced by 8% in commercial compressors) via sensorless BLDC controller and BLDC FOC controller.

• Proprietary Compressor Core Algorithm (compatible with mainstream compressor brands and R410A/R32 refrigerant systems)— the heart of our heat pump controller and inverter heat pump for swimming pool designs.

• Integrated High-Frequency PFC Inductor (THD < 5%) in our PFC power supply modules.

• Magnetic Saturation Compensation (iron loss reduced by 12% in commercial compressors).

Applications: VRF air conditioning systems, solar-powered ACs, commercial central air conditioning (ducted/ceiling-cassette/modular units), and refrigeration/freezing compressors. Provides safety-precompliant PCB architecture, supports split or integrated controller-driver layouts and refrigerant-cooled PCB processes.

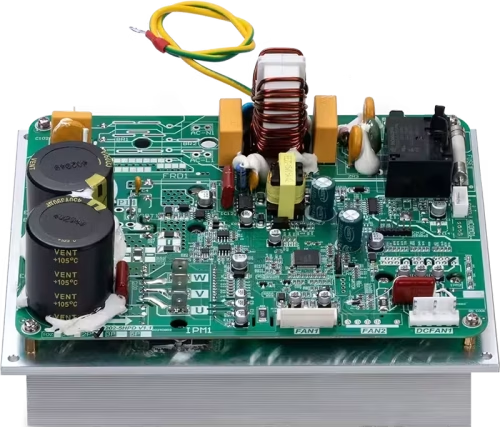

10HP BLDC Compressor Drive Board

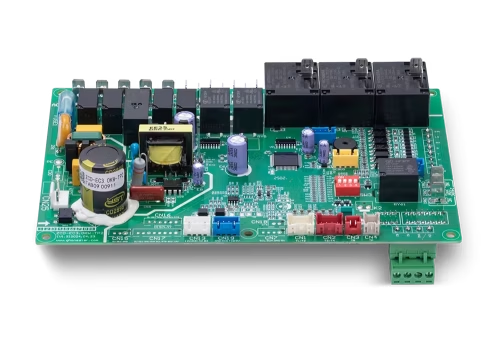

Heat Pump System Solution

Cold-start torque drop affects heating stability; water-pump vibration accelerates mechanical wear; traditional PFC response delay reducing PV utilization. Whether you need a thermostat for heat pump or an air source heat pump controller, our heat pump circuit board and 3 phase BLDC motor driver innovations include:

• 180° Sine Wave Vector Control (25% torque boost at-15°C@50% load) — critical for inverter heat pump for swimming pool and other low‑temperature starts.

• Adaptive Vibration Suppression (mechanical vibration reduced by 40%).

• High-Frequency Flux-Weakening Technology (speed regulation range 15:1).

• MTPA Control (copper loss reduced by 15% in heat pump motors).

• Proprietary Compressor Core Algorithm (compatible with mainstream compressor brands and R410A/R32 refrigerant systems).

• Three-Phase Interleaved PFC (efficiency >97.5%, PV interface tracking accuracy >99.5%).

• Magnetic Saturation Compensation (iron loss reduced by 10% in heat pump motors).

• Digital Power‑Switching Module (seamless MPPT input).

Applications: dual-supply/European triple-supply water heaters, swimming pool inverter heat pumps, air-source/water-source heat pump controllers; adopts refrigerant-direct-cooled PCB process (copper substrate + nano-coating), reserves CAN/Modbus interfaces for energy management expansion, supporting -30°C operational drive designs. Also ideal for heat pump circuit board replacement and heat pump control board upgrades.

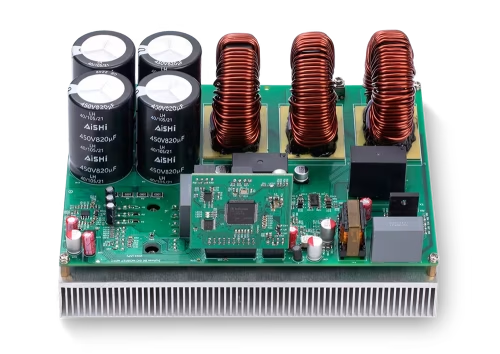

Inverter PTAC/HVAC & Heat Pump Control Board

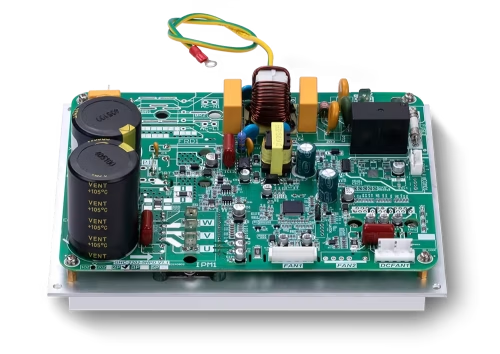

Motor Drive Solution

Start-stop current surges affect motor life; wide-range speed regulation inaccuracy impacting production quality; phase-loss/lock-rotor faults cause downtime; sudden load changes induce step-out. Our industrial DC motor controller and 3 phase BLDC motor controller platforms feature:

• AC 90-264V Wide-Voltage Design (global grid compatibility).

• Sensorless Sinusoidal Drive (0–100 000 RPM control) — a top-tier brushless DC motor driver.

• Proprietary FOC Algorithm (speed fluctuation <1%).

• Triple Protection Mechanism (phase-loss/overcurrent/lock-rotor response <10μs)

• 3 Resistor Current-Sense Topology (phase current accuracy ±2%).

• Input Over/Under-Voltage Protection (tolerates ±20% voltage fluctuation).

• Instant Start Technology (0.3s to full speed unloaded, real-time RPM LCD/LED display).

• Magnetic Saturation Suppression (core loss reduced by 20% in industrial motors).

• Ultra-Compact PCB Layout (optimized installation compatibility)

Applications: BLDC/PMSM motors, fans/pumps, lawnmowers, solar panel cleaning solutions, heat guns/hair dryers, concrete vibrators, and variable frequency drive air compressors; perfect for variable frequency drive air compressor applications and power supply PCB board integration. providing Infineon/ST dual-platform modular PCBs, supporting functional safety pre-certification architecture.

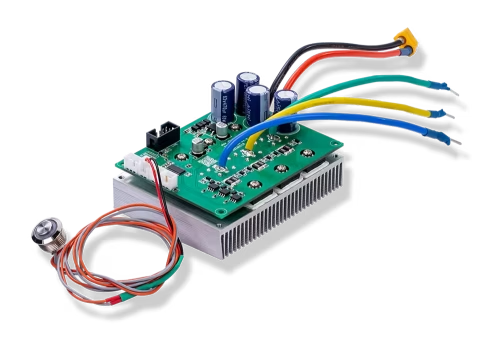

750W Sensorless FOC Lawn Mower Motor Drive Board

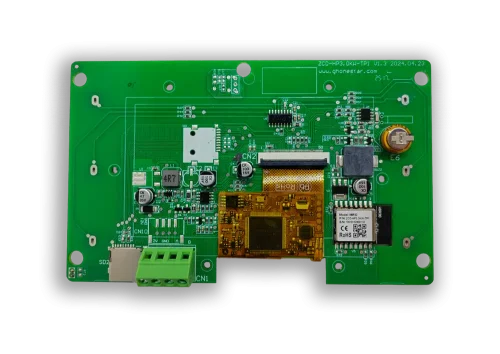

Power Electronics Solution

EMI conduction interference increases shielding cost; unidirectional energy flow limiting ESS applications; communication gaps hindering smart management; grid fluctuations triggering false protection; low power density of traditional topologies increasing cabinet space costs. Our PFC power supply and power electronics innovations include:

• Proprietary Digital PFC Algorithm (3kW single-phase supports DC-AC bidirectional operation).

• Bridgeless Totem-Pole PFC (99% peak efficiency, IEC 61000-3-2 Class C compliant).

• 7kW 3-Phase Full-Bridge B6 Topology (efficiency >97.5%, integrated WiFi/RS485 communication).

• Vienna 3-Level Architecture (high power density design for 18kW inverters).

• Adaptive Dead-Time Control (switching loss reduced by 15%).

• Isolated Modbus Communication (EMC immunity > 4 kV).

• Triple Protection Mechanism (overcurrent/overtemperature/overvoltage shutdown)

Applications: 3-20 kW PFC power supplies, 2.5 kW bidirectional inverters, 18 kW industrial inverters, energy-storage systems; providing OTA upgrade interfaces for remote parameter optimization.

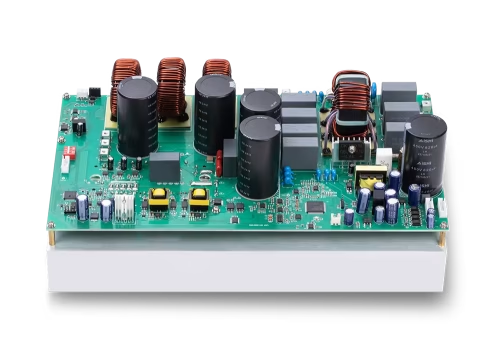

7 KW Three-Phase Digital PFC Front-end Rectifier Module

Technology Spotlight

Proprietary FOC Algorithm

Space Vector Control (SVPWM)

High-Efficiency PFC Technology

Multi-Platform Deep Development

Our Partner